-

AlexanderCredible suppliers

AlexanderCredible suppliers -

LouisIt's been a pleasure working with you

LouisIt's been a pleasure working with you

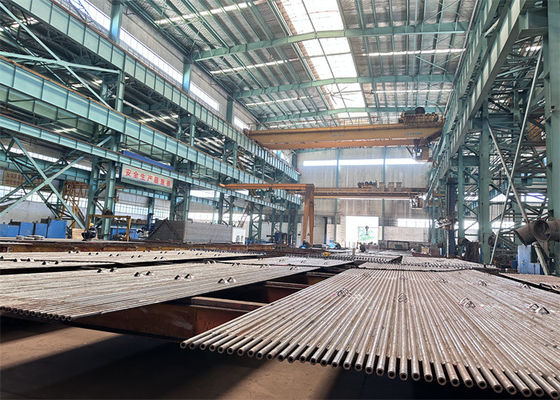

Power Plant Heating Surface Boiler Fin Tube Membrane Wall Panel SA192

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Durability | Long-lasting | Temperature Range | 500-1000°C |

|---|---|---|---|

| Flexibility | High | Heat Transfer Efficiency | Excellent |

| Pressure Range | 10-50 Bar | Installation Method | Welding |

| Corrosion Resistance | High | Thickness | Customzed |

| Highlight | Power Plant boiler fin tube,boiler fin tube Wall panel,SA192 membrane panel in boiler |

||

Power Plant Heating Surface SA192 Boiler Membrane Walls for Enhanced Corrosion Resistance

Product Description:

The Boiler Membrane Wall is customized according to the required thickness, ensuring that it fits perfectly with the specific needs of the boiler. The high flexibility of the panel allows it to adapt to the shape of the boiler without any difficulty, ensuring a perfect fit and a long-lasting solution.

The Boiler Membrane Wall is manufactured to comply with the highest standards of quality. It meets the requirements of the American Society of Mechanical Engineers (ASME), the European Norm (EN), and the International Organization for Standardization (ISO).

The high corrosion resistance of the Boiler Membrane Wall ensures that it can withstand the harsh conditions of the boiler environment. It is resistant to the corrosive effects of the hot gases and the chemicals present in the combustion process, ensuring a long-lasting and reliable solution.

The Boiler Membrane Wall is available in various materials, including carbon steel and alloy steel. Carbon steel is a popular choice due to its high strength and durability, while alloy steel is preferred for its superior resistance to corrosion and high-temperature environments. The choice of material depends on the specific requirements of the boiler and the operating conditions.

The Boiler Membrane Wall is a critical component in the construction of boilers. It is used in the rear water wall panel, which is an essential part of the boiler. The rear water wall panel is located in the rear of the boiler and is responsible for absorbing the heat generated by the combustion process. The Boiler Membrane Wall is used in this panel to ensure that it can withstand the high temperatures and pressures generated by the combustion process and provide a long-lasting and reliable solution.

In summary, the Boiler Membrane Wall is a customized panel made of carbon steel or alloy steel, with high flexibility and excellent corrosion resistance. It meets the highest standards of quality, including ASME, EN, and ISO. It is used in the construction of the rear water wall panel, an essential part of the boiler responsible for absorbing the heat generated by the combustion process. The Boiler Membrane Wall provides a long-lasting and reliable solution, ensuring the efficient operation of the boiler.

Features:

- Product Name: Boiler Menbrane Wall

- Application: Power Plant

- Heat Transfer Efficiency: Excellent

- Pressure Range: 10-50 Bar

- Thickness: Customized

- Installation Method: Welding

- SA192 Boiler Wall Membrane Component Assembly

- Can be used as a Boiler evaporation heating surface

Technical Parameters:

| Flexibility | High |

| Thickness | Customized |

| Standard | ASME, EN, ISO |

| Temperature Range | 500-1000°C |

| Corrosion Resistance | High |

| Pressure Range | 10-50 Bar |

| Application | Power Plant |

| Durability | Long-lasting |

| Installation Method | Welding |

| Material | Carbon Steel, Alloy Steel |

Applications:

The SANCO Boiler Wall Membrane System is a highly efficient and durable solution for industrial boilers. Made of high-quality carbon steel and alloy steel, this product is designed to withstand high temperatures ranging from 500-1000°C, making it ideal for use in various industrial applications.

The Side Water Wall Panel is a key component of the Boiler Wall Membrane System, which provides excellent insulation and corrosion resistance. The product meets ASME, EN, and ISO standards, and is certified by these organizations, ensuring its reliability and quality.

The SANCO Boiler Wall Membrane System is suitable for use in various industrial applications, including power generation, chemical processing, and petrochemical refining. The product is highly effective in preventing heat loss and reducing energy consumption, making it an ideal choice for companies looking to improve their energy efficiency and reduce costs.

In addition, the product is highly resistant to corrosion, making it ideal for use in harsh environments that are prone to corrosion. The pressure range of the product is 10-50 Bar, which makes it suitable for use in high-pressure applications where other products may fail.

The minimum order quantity for the SANCO Boiler Wall Membrane System is 3 tons, and the price is negotiable. The packaging details can be customized according to the customer's requirements, and the delivery time is 30 days. Payment terms are also negotiable, and the supply ability is 1500 tons per month.

In summary, the SANCO Boiler Wall Membrane System is a highly efficient and durable solution for industrial boilers. It meets various standards, is highly resistant to corrosion, and is suitable for use in various industrial applications. It is an ideal choice for companies looking to improve their energy efficiency and reduce costs.

Support and Services:

Our technical support and services for Boiler Membrane Wall product include:

- Expert installation guidance and supervision

- Training and education for product operators and maintainers

- Ongoing product maintenance and repair services

- 24/7 technical support hotline for any product-related issues or questions

- Regular product evaluations and assessments to ensure optimal performance

Packing and Shipping:

Product Packaging:

- The Boiler Menbrane Wall product will be packed securely in a wooden crate to ensure protection during transit.

- The crate will be labeled clearly with the product name, quantity, and any handling instructions.

Shipping:

- We offer worldwide shipping for the Boiler Menbrane Wall product.

- The shipping cost and estimated delivery time will be provided at the time of purchase.

- Please note that any customs duties or taxes imposed by the destination country will be the responsibility of the customer.

FAQ:

Q: What is the brand name of the boiler membrane wall product?

A: The brand name of the boiler membrane wall product is SANCO.

Q: Where is the boiler membrane wall product manufactured?

A: The boiler membrane wall product is manufactured in China.

Q: What certifications does the boiler membrane wall product have?

A: The boiler membrane wall product has ISO, ASME, and EN certifications.

Q: What is the minimum order quantity for the boiler membrane wall product?

A: The minimum order quantity for the boiler membrane wall product is 3 tons.

Q: What is the price of the boiler membrane wall product?

A: The price of the boiler membrane wall product is negotiated.

Q: What are the packaging details for the boiler membrane wall product?

A: The packaging details for the boiler membrane wall product are customized.

Q: What is the delivery time for the boiler membrane wall product?

A: The delivery time for the boiler membrane wall product is 30 days.

Q: What are the payment terms for the boiler membrane wall product?

A: The payment terms for the boiler membrane wall product are negotiated.

Q: What is the supply ability of the boiler membrane wall product?

A: The supply ability of the boiler membrane wall product is 1500 ton/month.