-

AlexanderCredible suppliers

AlexanderCredible suppliers -

LouisIt's been a pleasure working with you

LouisIt's been a pleasure working with you

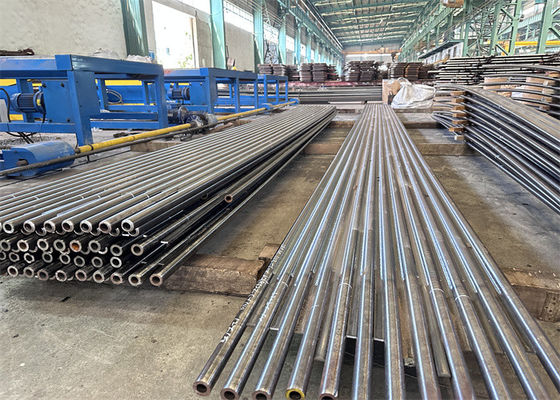

ASME Approved Boiler Wall Membrane System for Chemical Industry

| Corrosion Resistance | High | Temperature Range | 500-1000°C |

|---|---|---|---|

| Standard | ASME, EN, ISO | Application | Power Plant |

| Material | Carbon Steel, Alloy Steel | Thickness | Customzed |

| Durability | Long-lasting | Heat Transfer Efficiency | Excellent |

| Highlight | ASME Approved Boiler Wall Membrane |

||

Product Description:

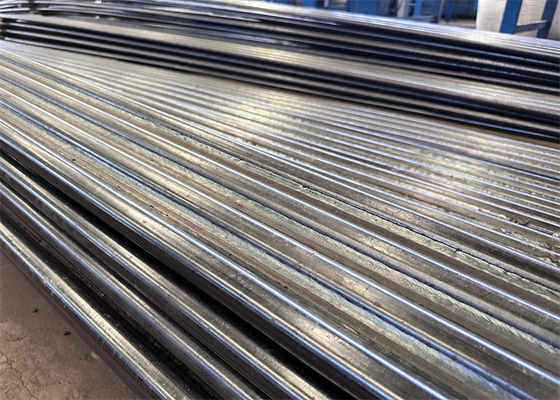

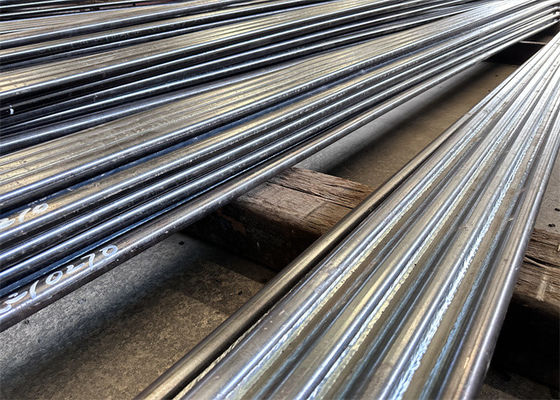

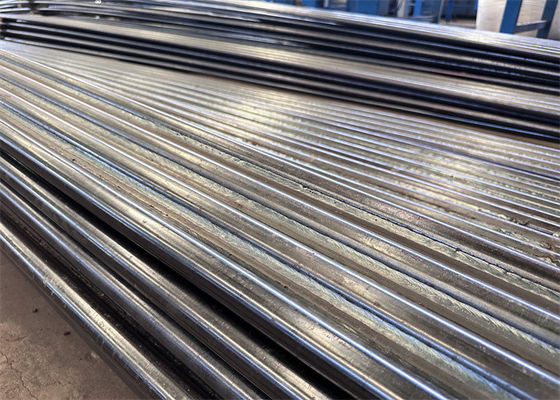

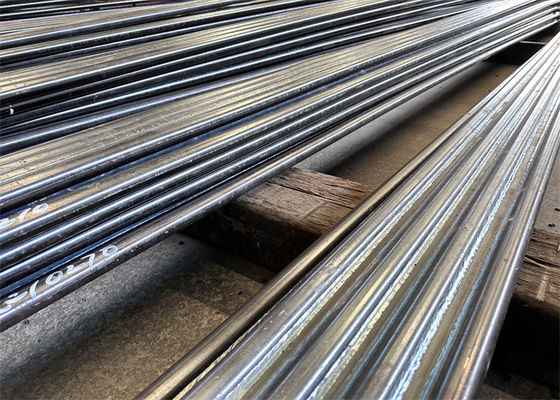

Our Boiler Wall Membrane System is highly flexible, allowing it to conform to the shape of any boiler wall, regardless of size or shape. This makes installation a breeze, as our product can be easily tailored to your needs.

With a temperature range of 500-1000°C, our Boiler Wall Membrane System is built to withstand even the most extreme temperatures found in boiler environments. This ensures that your boiler will remain safe and efficient, even under the harshest conditions.

The thickness of our Boiler Wall Membrane System is fully customizable, allowing you to choose the thickness that best suits your needs. This ensures that you receive a product that is tailored to your specific requirements, ensuring optimal performance and energy efficiency.

Our Boiler Wall Membrane System is highly resistant to corrosion, ensuring that your boiler remains safe and efficient for years to come. This makes our product a cost-effective investment, as it reduces the need for costly repairs and replacements in the future.

So why wait? Invest in our top-of-the-line Boiler Wall Membrane System today and experience the benefits of a highly flexible, temperature-resistant, corrosion-resistant product that is built to meet the highest standards in the industry.

Features:

- Product Name: Boiler Menbrane Wall

- Heat Transfer Efficiency: Excellent

- Flexibility: High

- Installation Method: Welding

- Pressure Range: 10-50 Bar

- Corrosion Resistance: High

- Material: SA210A1, SA210C

- Usage: Boiler evaporation heating surface, Protective furnace wall

Technical Parameters:

| Product Attribute | Value |

| Product Name | Boiler Wall Membrane Unit |

| Alternative Name | Side Water Wall Panel, Boiler Wall Membrane Panel |

| Thickness | Customized |

| Flexibility | High |

| Standard | ASME, EN, ISO |

| Corrosion Resistance | High |

| Application | Power Plant |

| Material | Carbon Steel, Alloy Steel |

| Heat Transfer Efficiency | Excellent |

| Installation Method | Welding |

| Durability | Long-lasting |

| Temperature Range | 500-1000°C |

Applications:

The packaging details of the product can be customized according to the customer's request. The delivery time for the product is 30 days and the payment terms are also negotiated. The supply ability of this product is 1500 tons per month which makes it readily available for customers.

The material used in this product is carbon steel and alloy steel which are known for their high corrosion resistance and durability. The standard followed for this product is ASME, EN, and ISO. The thickness of the product can be customized according to the requirements of the customer.

The Boiler Wall Membrane System is specifically designed to protect the furnace wall of the boiler. The product is able to withstand high temperatures ranging from 500-1000°C. It is ideal for use in environments where there is a high risk of corrosion or damage to the furnace wall.

The product is suitable for a wide range of applications including power plants, chemical plants, and other industrial facilities. It is especially useful in scenarios where the furnace wall is exposed to high temperatures, corrosive materials, and other harsh conditions.

In conclusion, the SANCO Boiler Wall Membrane System is a high-quality product that is designed to protect the furnace wall of the boiler. It is suitable for a wide range of applications and is made from durable materials that are resistant to corrosion. The product is able to withstand high temperatures and is available in various thicknesses to meet the needs of customers.

Support and Services:

The Boiler Membrane Wall product technical support and services include:

- Installation assistance and consultation

- Equipment maintenance and repair

- Equipment upgrades and retrofits

- Inspection and testing services

- Training and education for operators and maintenance personnel

- 24/7 technical support and emergency services

Our team of experienced professionals is dedicated to providing top-quality support and services to ensure the efficient operation and longevity of your boiler membrane wall system.

Packing and Shipping:

Product Packaging:

- The Boiler Menbrane Wall product will be packaged in wooden crates to ensure maximum protection during transportation.

- The crates will be labeled with the product name, size, and quantity to ensure easy identification.

- Each crate will also include a packing list for verification purposes.

Shipping:

- The Boiler Menbrane Wall product will be shipped via sea, air or land transportation depending on the customer's preference.

- Shipping costs will be calculated based on the weight and volume of the product as well as the shipping destination.

- The customer will be responsible for any customs fees or duties associated with the shipment.

- Once the product has been shipped, the customer will receive a tracking number to monitor the status of the shipment.