-

AlexanderCredible suppliers

AlexanderCredible suppliers -

LouisIt's been a pleasure working with you

LouisIt's been a pleasure working with you

Argon Arc Welded Membrane Walls High Pressure Heating For Biomass Boilers

| Place of Origin | Zhangjiagang China |

|---|---|

| Brand Name | SANCO |

| Certification | ISO9001 , ASME, TUV,EN |

| Model Number | Boiler Membrane Wall |

| Minimum Order Quantity | 1Set |

| Price | Negotiable |

| Packaging Details | Iron Frame ASME Standard Packing |

| Delivery Time | 30 |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 1500 Tons / Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Fuel | Coal/Gas/Oil-fired, Water Heat | Type | Automatic Submerged Arc Welding |

|---|---|---|---|

| Range Of Applications | Power Plant | Specification | ASME Inspection |

| Inspection | ASME Inspection | Size | Customized |

| Fuel Of Boiler | Coal/Gas/Coal-fired/Water Heat | Keywords | Boiler Membrane Wall |

| Materials | Carbon Steel / Stainless Steel | Color | Customized |

| Highlight | Argon Arc Welded Membrane Walls,Biomass Boilers Membrane Walls,High-Pressure Membrane Walls |

||

Argon Arc Welded Membrane Walls High-Pressure Heating For Biomass Boilers

Critical manufacturing processes?

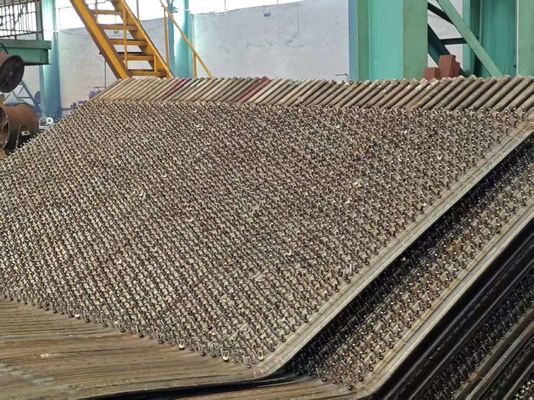

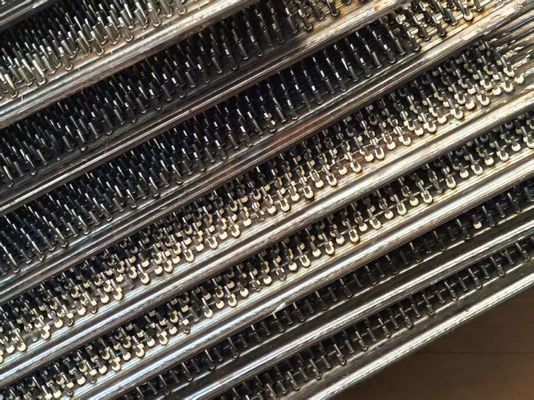

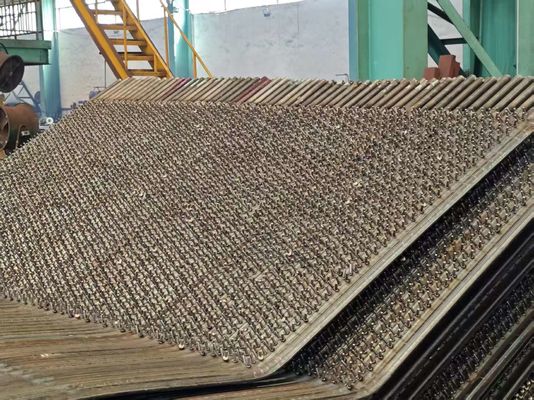

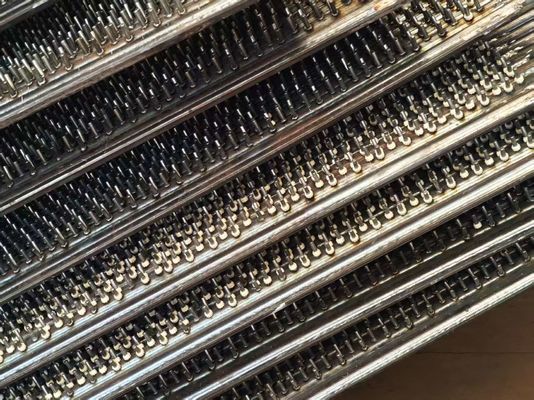

HF resistance welding (fin-tube) + post-weld heat treatment (stress relief).

Description:

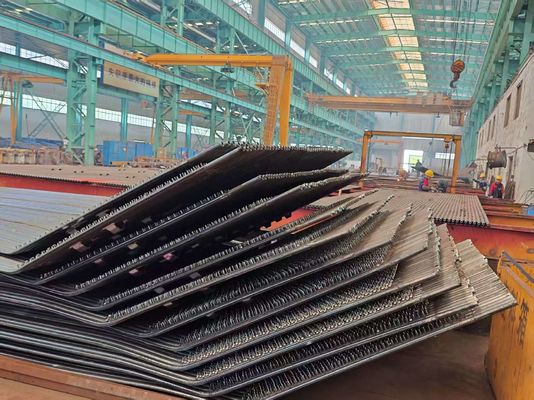

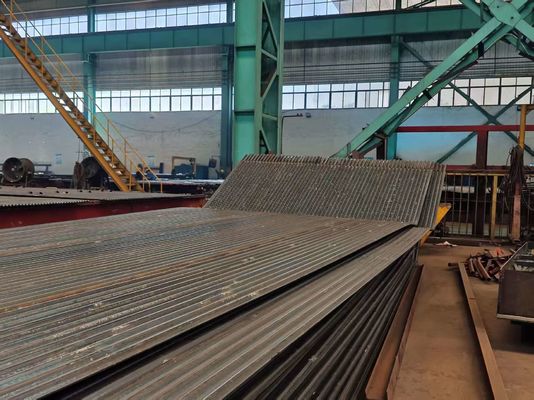

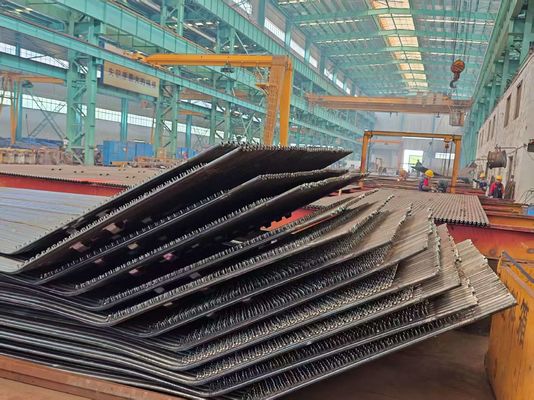

Water wall panels are used in Waste Heat recovery boilers. We manufacture Water wall panels. These are fabricated out of carbon steel tubes to customers' drawings and specifications. Special care is taken for ovality and thinning at the bent portion, during fabrication.

We are manufacturing and supplying a comprehensive range of Waterwall Panels. The tubes offered by us are known to withstand a great internal pressure as a continual strip of fin material is wound spirally on the tube. These tubes are known to provide heat uniformly that result in an increased heat output.

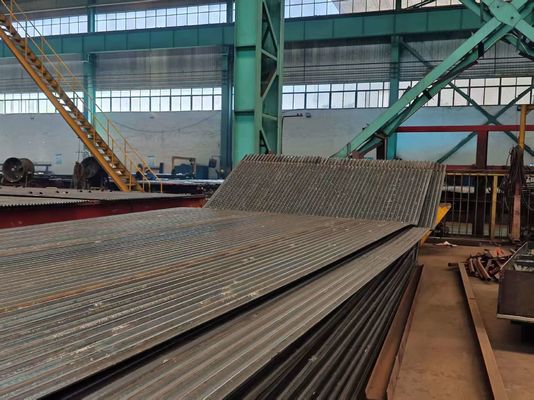

The main function of water wall panels in boiler is to absorb the heat generated by high temperature flame or flue and to generate steam or hot water in tubes, hence to reduce the temperature in the chamber.

Product Introduction

Advantages of Membrane Water Wall

1). To guarantee the leakproofness of furnace wall and reduce the air leak of combustion chamber.

2). To achieve the full water cooling of combustion chamber, and the boiler accessories membrane water wall is benefit to prevent coking under the condition of supplemental firing.

3). The thermal storage capacity is small, the warming of combustion chamber is fast and the cooling is also fast, which could shorten the cooling time of boiler’s start and furnace shut down.

4). It is good to adopt top supported water cooled wall and it could reduce the load of boiler framework, which is benefit to overhang.

5) Compared with the bare tubes, the membrane water wall improves the heat absorption capacity of tubes.

6) The factory direct boiler membrane water wall could improve the Preliminary combination degree of boiler parts and reduce the installation workload.

Application

| 1 | Energy saving enviromental protection china supplier membrane water wall for CFB boiler are membrane walls that are made of tubes welded together with or without a strip of metal in between. |

| 2 | These walls form the enclosure of the coal combustion chamber. |

| 3 | Water wall tubes are also referred to as the evaporator section; they contain water mostly in liquid form which gradually evaporates as it rises in the boiler. |

![]()

Additional

| 1 | Water wall panels are used in Waste Heat recovery boilers. |

| 2 | We manufacture Water wall panels,these are fabricated out of carbon steel tubes to customers' drawings and specifications. |

| 3 | Special care is taken for ovality and thinning at the bent portion,during fabrication. |

| 4 | We are manufacturing and supplying a comprehensive range of Waterwall Panels. |

| 5 | The tubes offered by us are known to withstand a great internal pressure as a continual strip of fin material is wound spirally on the tube. |

| 6 | These tubes are known to provide heat uniformly that result in an increased heat output. |

| 7 | The main function of water wall panels in boiler is to absorb the heat generated by high temperature flame or flue and to generate steam or hot water in tubes, hence to reduce the temperature in the chamber. |

Note

| 1 | Control of weld penetration to satisfy mechanical and heat transfer requirements Control of the deformation to acceptable tolerances. |

| 2 | Panels routinely require straightening in the workshop after welding and heat treatment, the question to be answered is can the shop then meet the required dimensional tolerances for successful site installation? |

| 3 | Can existing shop handling procedures be used as-is without adding excessive controls that will add cost and schedule. |

| 4 | The importance of preheating and its maintenance through the welding process could cause a number of handling and shop processing issues that will substantially increase cost. |