-

AlexanderCredible suppliers

AlexanderCredible suppliers -

LouisIt's been a pleasure working with you

LouisIt's been a pleasure working with you

Customizable ASTM Certified Water Wall Panels For Coal Boiler Evaporation Section

| Function | Wall Decoration And Heat Insulation | Maintenance | Low |

|---|---|---|---|

| Fireproof | Grade A | Installation Method | Welding |

| Flexibility | High | Hs Code | 3215960855 |

| Welding Technique | Submerged Arc Welding | Tube Material | SA 210 A1 |

| Pressure Resistance | High | Color | Customized |

| Range Of Applications | Industrial/Power Station | Insulation | Excellent |

| Highlight | ASTM Certified Water Wall Panels,ASTM Water Wall Panels,Coal boiler membrane wall |

||

Customizable ASTM-Certified Water Wall Panels For Coal Boiler Evaporation Section

What is a boiler membrane wall?

It's a welded panel construction where tubes are joined by steel membranes to form gas-tight furnace walls.

Introduction

- A membrane water wall is an airtight structure created by combining pipes and fins. This design forms a seamless barrier that plays a crucial role in boiler operations.

- Advantages:

- Reduced Air Leakage: Its airtight nature minimizes air leakage inside the furnace, ensuring more efficient combustion and energy use.

- Cost & Structural Benefits: By using pipe - laying walls, it lessens the load on the steel structure, which in turn cuts down the overall cost of the boiler.

- Flexible Design: It’s easy to incorporate a suspension structure, which helps improve the thermal expansion system. This adaptability makes it ideal for large - scale mechanized production, with a high assembly rate.

- Faster Start - up & Shutdown: Thanks to its low heat storage capacity, it can significantly shorten the start - up and shutdown time of the boiler, saving both time and energy.

- Disadvantage: However, the manufacturing process of membrane water walls is rather complex, requiring advanced techniques and careful assembly.

- Applications: Given its features, membrane water walls are commonly used in large - capacity, high - temperature, and high - pressure boilers, where efficiency and durability are key.

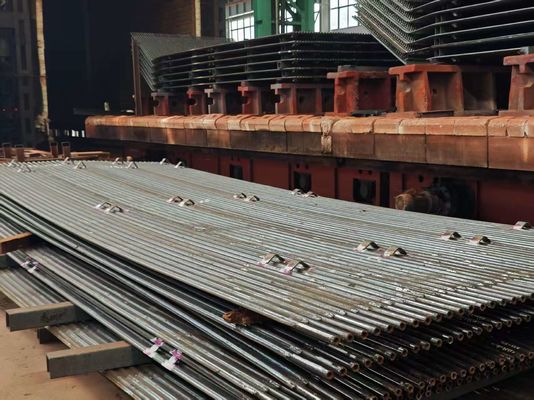

![]()

Strong points of membrane water wall

(1) Ensure the sealing of furnace wall and reduce air leakage in combustion chamber.

(2)The realization of full water cooling in combustion chamber is beneficial to prevent coking under the condition of intensified combustion.

(3)The cooling time of start-up and shutdown of boilers can be shortened because of its small heat storage capacity, fast temperature rise and fast cooling in combustion chamber.

(4)Pipe-laying furnace wall is suitable, which greatly reduces the load of boiler frame and it is convenient for suspension and lifting.

(5)Compared with the bare tube type, the heat absorption capacity of the tube is improved.

(6)It improves the per-assembly degree of boiler components, facilitates and reduces the installation workload

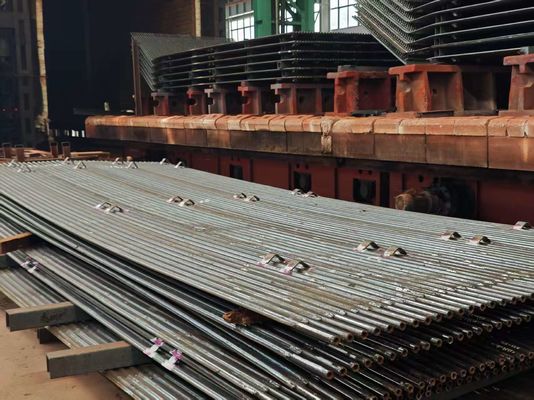

![]()

Various Boiler Water Wall Panel Can Be Fabricated besides the membrane wall type:

- Membrane boiler water wall panel: spot welds many rolled finned tubes into a sealed combined heating surface, which improves the airtightness of the furnace and reduces air leakage.

- Studded water wall tubing: welds pins of 20 to 25 mm in length and 6 to 12 mm in diameter on the water wall tube, and then applies a chrome ore refractory plastic to reduce the water wall panel’s heat absorption, and increase the temperature in the combustion zone. It is appropriate for situations where it is difficult to set fire to the fuel, as well as specific slag tapping furnaces.

- Plain tube boiler water wall panel: composed of a whole row of seamless steel pipes, the simplest structure.

- Wall-attached boiler water wall tubing: embedded in the inner wall of the furnace wall, single-sided heat absorption.

- Double-sided heated water wall panel: installed in the middle of the large boiler furnace, which is divided into two parts that are independent of each other, and both sides are heated.