-

AlexanderCredible suppliers

AlexanderCredible suppliers -

LouisIt's been a pleasure working with you

LouisIt's been a pleasure working with you

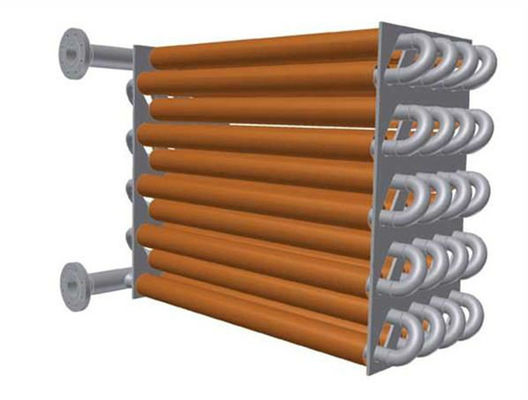

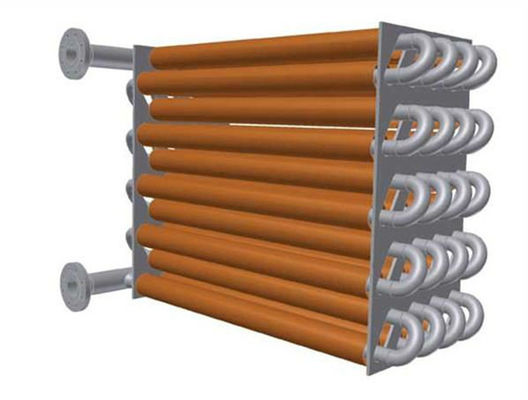

Power Station CFB Boiler Economizer with Central Heating and 1 Year Warranty ASTM Certification

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Natural Circulation | Structure | Fire Tube And Water Tube |

|---|---|---|---|

| Pressure | Low / High Pressure | Style | VERTICAL |

| Fuel | Coal / Gas / Coal-fired / Water Heat | Output | Hot Water / Steam |

| Weight | 20000 KG | Surface Treatment | Painted |

| Bare Pipe OD | 25-1650 Mm | Bare Pipe Thickness | 2-40 Mm |

| Fin Thickness | 0.6-3.0 Mm | Fin Height | 5-30 Mm |

| Fin Tube Pitch | 5-30 Mm | Fin Tube Length | ≤12000 Mm |

| Material | Carbon Steel, Alloy, Austenitic Steel | ||

| Highlight | Power Station CFB Boiler Economizer,Central Heating Boiler Economizer,1 Year Warranty Boiler Economizer |

||

An economizer is a mechanical device designed to reduce energy consumption by preheating fluids. This CFB boiler economizer is used in power plants, heating systems, and HVAC applications, functioning as an efficient heat exchanger to improve overall system performance.

The primary function of this economizer is to reduce cooling costs by minimizing compressor operation time while maintaining adequate cooling capacity, resulting in significant energy savings.

| Name (unit) | Specification (mm) |

|---|---|

| Bare pipe (OD) | 25-1650 |

| Bare pipe (Thickness) | 2-40 |

| Fin (Thickness) | 0.6-3.0 |

| Fin (Height) | 5-30 |

| Fin tube thread pitch | 5-30 |

| Fin tube length | ≤12000 |

Material: Carbon Steel, Alloy, Austenitic Steel (Nickel and Chromium or Manganese)

- Impact test and Strength calculation report with applied materials information

- 100% NDT (non-destructive inspection) report of steel plate, tube and electrode

- X-ray, γ-ray and liquid penetrant test inspection report (welding seam)

- Hydraulic test report to ensure standard working pressure and safety