-

AlexanderCredible suppliers

AlexanderCredible suppliers -

LouisIt's been a pleasure working with you

LouisIt's been a pleasure working with you

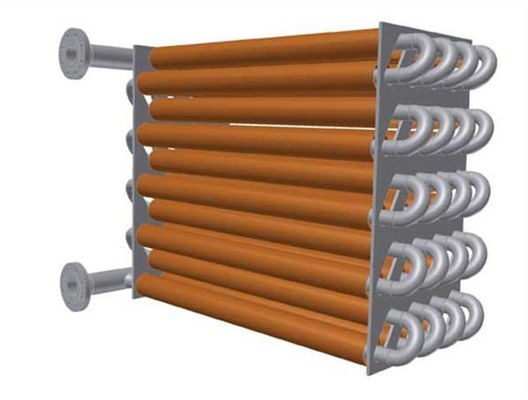

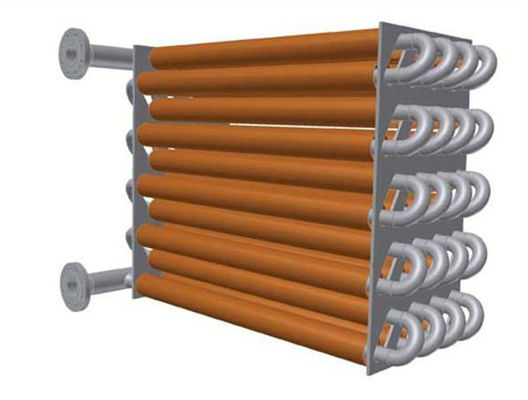

High Pressure Boiler Economizer Heat Exchanger with 3 Years Warranty and 1-20 Ton Capacity

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Natural Circulation | Usage | Power Station |

|---|---|---|---|

| Structure | Water Tube | Pressure | High Pressure |

| Steam Production | Max. 20t/h | Style | Horizontal |

| Output | Hot Water | Design Fuel | Coal Fuel |

| Material | Special Boiler Steel Plate | Fuel Type | Coke Oven Gas |

| Weight | 1-20 Ton | Smelting Process | EF+LF + VD |

| UT Standard | ASTM A388 Or EN10228 | Material Standard | ASTM, EN Or ISO |

| Process | Material->Ingot -> Hot/Cold-Rolling-> Heat Treatment (Normalizing+ Tempering) -> Inspection ->rough Machining->UT ->2nd Heat Treatment ->finishing Machining ->Inspection | ||

| Highlight | High Pressure Boiler Economizer,3 Years Warranty Heat Exchanger,1-20 Ton Boiler Economizer |

||

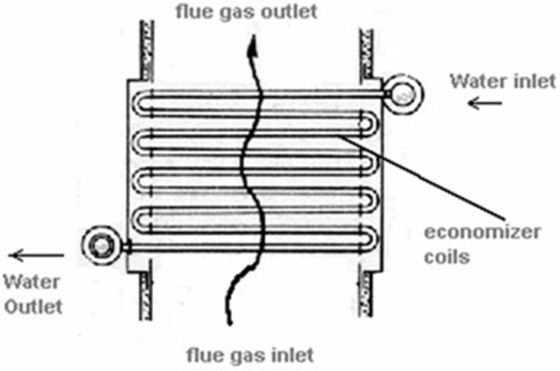

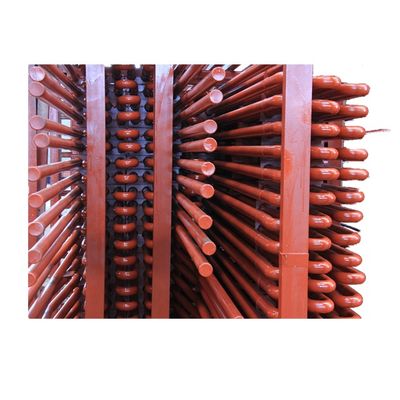

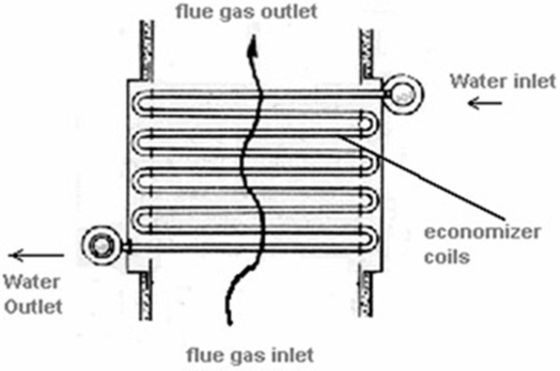

Boiler economizers are heat exchange devices with finned tubes that heat liquids (typically water) to temperatures below their boiling point. We manufacture three types of boiler economizers:

- Bare tube economizer

- H-finned tube economizer

- Spiral finned tube economizer

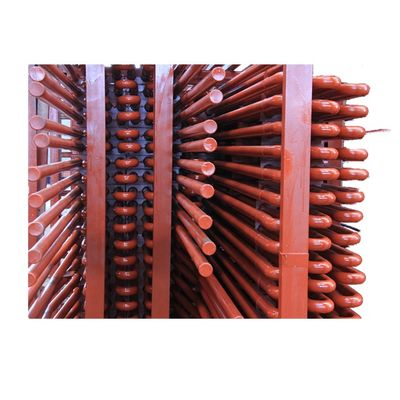

The H-finned tube economizer is a highly efficient heat exchanger consisting of H-finned tubes. Compared to bare tube economizers, it offers:

- Expanded heat exchange area

- Reduced number of required tubes

- Increased flue gas flow area

- Reduced flue gas flow speed and abrasion

Our H-finned tubes can be manufactured as double H-finned tubes with high rigidity to accommodate long tube rows. The spiral finned economizer is our innovative design featuring spiral fin tubes to overcome abrasion issues and extend service life.

| Description | Boiler economizer |

|---|---|

| Material | Alloy steel, Carbon steel, SA210C, SA213T22, etc. |

| Material standard | ASTM, EN or ISO etc. |

| Dimension | Customization |

| Weight | Min: 10 ton Max: 1000 ton |

| Smelting Process | EF+LF+VD |

| Process | Material→Ingot→Hot/Cold-Rolling→Heat treatment (Normalizing+ tempering)→Inspection→rough machining→UT→2nd Heat treatment→finishing machining→Inspection |

| UT standard | ASTM A388 or EN10228, etc. |

- Impact test and Strength calculation report with applied materials information

- 100% NDT (non-destructive inspection) report of steel plate, tube and electrode

- X-ray, γ-ray and liquid penetrant test inspection report (welding seam) to ensure boiler quality

- Hydraulic test report to verify standard working pressure and safety

Address: No.1 Dongli Road, Donglai, Zhangjiagang City, Jiangsu Province, China

Tel: +86 (0) 512 5866 6196

Fax: +86(0) 512 5877 4453

Web: www.boilerfabrication.com