-

AlexanderCredible suppliers

AlexanderCredible suppliers -

LouisIt's been a pleasure working with you

LouisIt's been a pleasure working with you

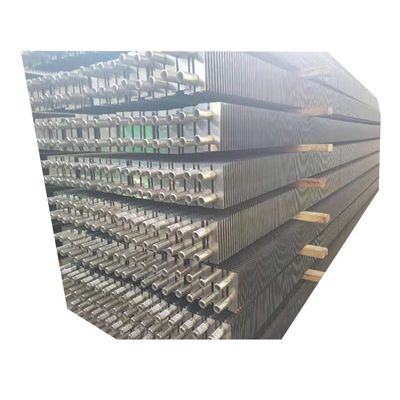

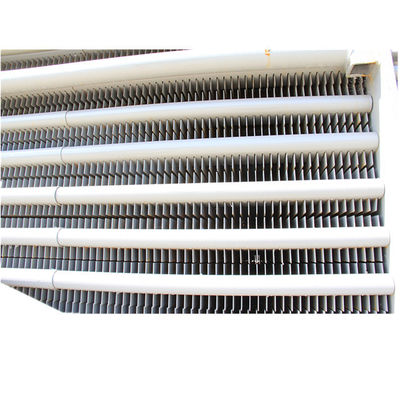

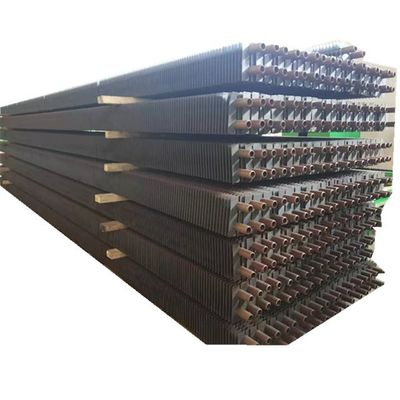

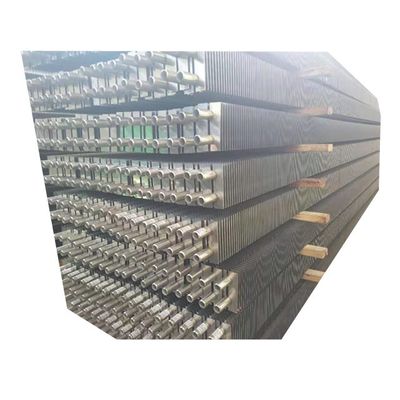

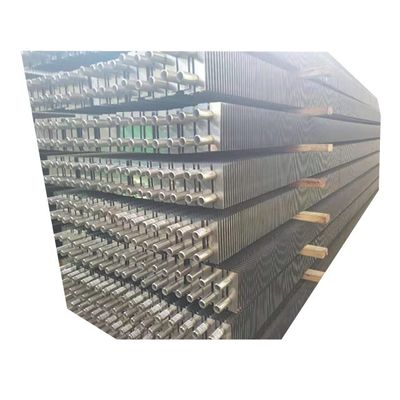

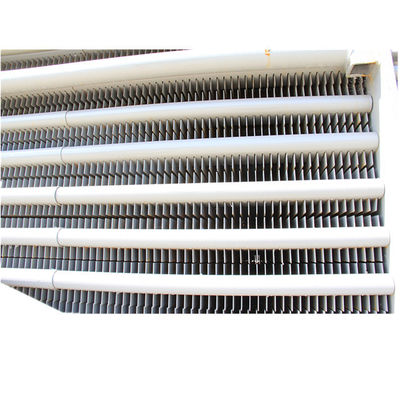

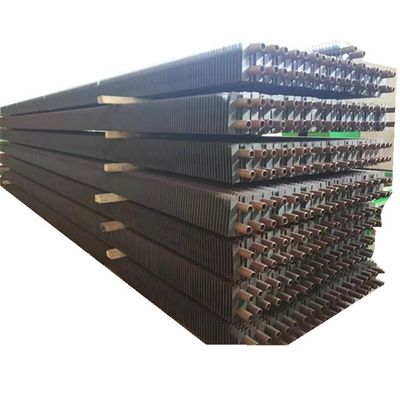

H Fin Tube Economizer with Max 20t/h Steam Production 1 Year Warranty and 5 Years Core Components Warranty

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Natural Circulation | Structure | Fire Tube And Water Tube |

|---|---|---|---|

| Pressure | Low / High Pressure | Steam Production | Max. 20t/h |

| Style | VERTICAL | Fuel | Coal / Gas / Coal-fired / Water Heat |

| Output | Hot Water / Steam | Surface Treatment | Painted |

| Material | Alloy Steel, Carbon Steel, SA210C, SA213T22 | Material Standard | ASTM, EN Or ISO |

| Weight Range | 10 Ton - 1000 Ton | Smelting Process | EF+LF + VD |

| Process | Material->Ingot->Hot/Cold-Rolling->Heat Treatment->Inspection->rough Machining->UT->2nd Heat Treatment->finishing Machining->Inspection | UT Standard | ASTM A388 Or EN10228 |

| Heat Exchanger Type | H-finned Tube Economizer | ||

| Highlight | Max 20t/h Steam Production H Fin Tube Economizer,1 Year Warranty H Fin Tube Economizer,5 Years Core Components Warranty H Fin Tube Economizer |

||

Boiler economizers are high-efficiency heat exchange devices with finned tubes designed to heat liquids (typically water) without reaching boiling point. We manufacture three types of boiler economizers:

- Bare tube economizer

- H finned tube economizer

- Spiral finned tube economizer

- Enlarges heat exchange area while reducing number of tubes required

- Increases flue gas flow area to reduce flow speed and abrasion

- Available in double H finned tube configuration for enhanced rigidity in long tube rows

- Superior to bare tube designs in efficiency and durability

The economizer significantly reduces cooling costs by optimizing heat transfer efficiency, allowing for compressor shutdowns while maintaining adequate cooling capacity.

| Description | Boiler economizer |

|---|---|

| Material | Alloy steel, Carbon steel, SA210C, SA213T22 |

| Material standard | ASTM, EN or ISO |

| Dimension | Customizable |

| Weight | 10-1000 tons |

| Smelting Process | EF+LF+VD |

| Manufacturing Process | Material→Ingot→Hot/Cold-Rolling→Heat treatment→Inspection→Rough machining→UT→2nd Heat treatment→Finishing machining→Final inspection |

| UT standard | ASTM A388 or EN10228 |

- Impact test and strength calculation reports with material information

- 100% NDT (non-destructive testing) of steel plate, tube, and electrode

- X-ray, γ-ray, and liquid penetrant test inspection for all welding seams

- Hydraulic test reports to verify working pressure and safety standards