-

AlexanderCredible suppliers

AlexanderCredible suppliers -

LouisIt's been a pleasure working with you

LouisIt's been a pleasure working with you

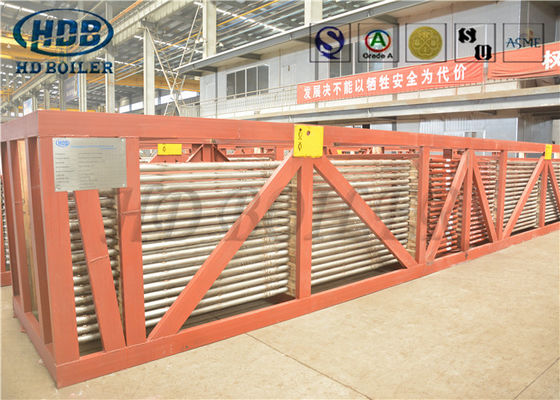

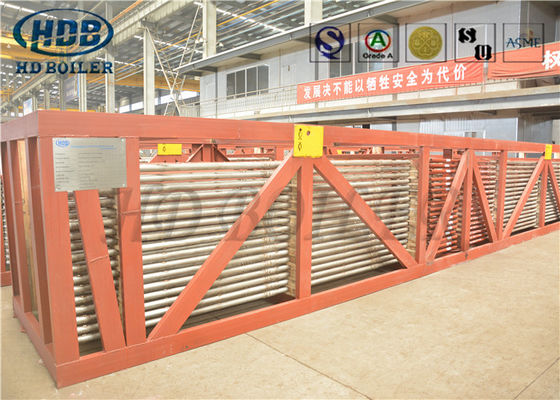

Waste Heat Recovery H Fin Tube High Frequency Welding Industrial Boiler Economizer ASME

| Place of Origin | Zhangjiagang China |

|---|---|

| Brand Name | SANCO |

| Certification | ISO9001 , ASME, TUV,EN |

| Model Number | Boiler Economizer |

| Minimum Order Quantity | 1Set |

| Price | Negotiable |

| Packaging Details | Iron Frame ASME Standard Packing |

| Delivery Time | 30 |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 1500 Tons / Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Fuel | Coal/Gas/Oil-fired, Water Heat | Type | Primary And Secondary |

|---|---|---|---|

| Range Of Applications | Power Plant | Specification | ASME Inspection |

| Inspection | ASME Inspection | Dimension Of Tube | 38.1*3.2 |

| Fuel Of Boiler | Coal/Gas/Coal-fired/Water Heat | Keyword | Keyword |

| Keywords | Boiler Economizer | Materials | Carbon Steel / Stainless Steel |

| Usage | Power Plant/CFB Boiler | ||

| Highlight | ASME Industrial Boiler Economizer |

||

Waste Heat Recovery H Fin Tube High Frequency Welding Industrial Boiler Economizer ASME

Performance characteristics:

- 1. Excellent anti-wear performance

- 2. Less fouling

- 3. Compact space

- 4. Welded Joints less

- 5. Stability

Parameter

| Name(unit) | Specification(mm) |

| Bare pipe(OD) | 25-165 |

| Bare pipe(Thickness) | 2-8 |

| Fin (Thickness) | 0.6-3.0 |

| Fin (Height) | 5-30 |

| Fin tube thread pitch | 5-30 |

| Fin tube length | ≤12000 |

*Note:HD BOILER can bespoke special type of economizer according to customer's requirement.

Specification:

- CFB series energy saving boiler high quality economizer is a heat exchanger device that captures the "lost or waste heat" from the boiler's hot stack gas.

- The latest technology boiler spiral finned tubes economizer typically transfers this waste heat to the boiler's feed-water or return water circuit, but it can also be used to heat domestic water or other process fluids. This is the introduction about CFB series energy saving boiler high quality economizer.

Manufacturing and acceptance criteria:

· JB/T6512 "boiler with a high-frequency resistance welding spiral fin tube manufacturing technology conditions"

· HG/T3181 "high-frequency resistance welding spiral fin tube"

· JB/T6511 "spiral finned tube test technical conditions."

· JB1611 "boiler tube mane box assembly conditions"

· JB/T1612 "boiler pressurufacturing conditions."

· JB16I3 "boiler pressure parts welding conditions."

![]()

Company Introduction

HD Boiler offers a best in class facility,including:

- Fabrication area of 200,000 square meters

- 150 Engineers

- 600 Coded welders

- 60 Licensed Inspectors (including NDT level-lll instructors)

- Grade-ALicenses for Design and Manufacture boiler (issued by the State Administration of Quality Supervision and Inspection)

- ISO 90001:2008 Quality System

- ASME Certificate of Utility Boiler

- ASME‘S’ , ‘U’ and NB stamp authorization